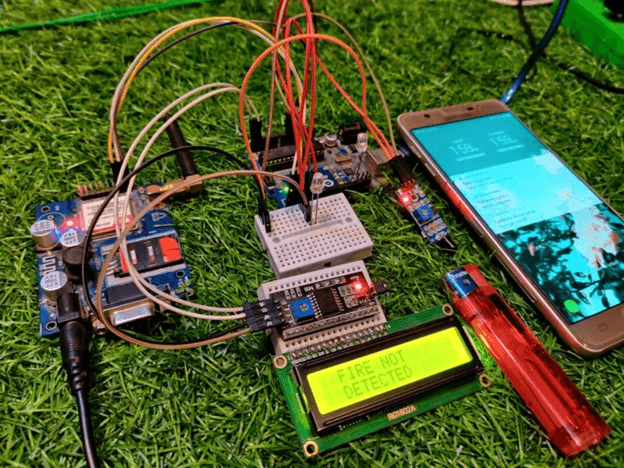

GSM‑Based Pump Controller: A remote system using GSM technology for monitoring and controlling pumps in applications like irrigation, water supply, and industrial processes. Key features include SMS or missed-call control, real-time status updates (e.g., power failure, pump on/off), and robust components like microcontrollers, GSM modules, and sensors.

GSM Based Project

ATM Alerts

GSM-based ATM alert systems are projects designed to enhance the security and monitoring of Automated Teller Machines (ATMs) using GSM (Global System for Mobile Communications) technology. These systems can send alerts and notifications in real-time to ensure quick responses to any irregularities or emergencies. Here are some key features, components, and applications of such systems:

Key Features

Real-Time Alerts: The system sends instant SMS notifications to bank or security staff when:

An ATM is tampered with or vandalized.

Cash levels drop below a threshold.

Malfunctions or technical issues occur.

- Intrusion Detection: Sensors can detect unauthorized access or tampering, triggering alerts immediately.

Cash-Level Monitoring: Sensors track ATM cash levels and send alerts when they dip below a set threshold.

Power-Failure Alerts: Instantly notifies the team during power outages or restoration events for prompt action .

Remote Monitoring: Bank officials receive SMS alerts to remotely monitor ATM status and respond quickly.

Components

-

Microcontroller: Serves as the central processor, handling sensor inputs and directing the GSM module.

-

GSM Module: Sends SMS alerts to designated numbers to report events.

-

Sensors: Include motion detectors, cash-level sensors, and temperature monitors to detect various conditions.

-

Power Supply: Provides stable power—typically via voltage regulators like 7805 or battery backup—to keep the system running even during outages.

Applications

Banking & Finance: Enhances ATM and vault security to minimize fraud and theft.

Retail: Integrates with POS systems to notify staff about malfunctions or low stock via SMS alerts.

Security: Monitors equipment and facilities across industries, sending real-time alerts to ensure safety and prompt action.

Benefits

Enhanced Security: Instant alerts deter theft and vandalism by enabling timely intervention.

Operational Efficiency: Continuous cash-level and system monitoring helps banks optimize replenishment and maintenance cycles.

Cost-Effective: Automates surveillance and reduces reliance on physical guarding, lowering operational costs.

Pump Controller

Key Features

-

Remote Control: Start or stop the pump remotely via SMS commands sent to the GSM module.

-

Monitoring: Receive SMS alerts on pump status, including operation, faults, and malfunctions.

-

Automated Scheduling: Set timers or schedules for automatic pump operation to minimize manual intervention.

-

Water-Level Sensing: Integrate sensors to monitor tank/reservoir levels and control the pump accordingly.

-

Fault Detection: Send alerts for issues like dry running, overload, or failure to start.

Components

Microcontroller: Central processor that reads sensor inputs and controls the pump via relay.

GSM Module: Sends and receives SMS to facilitate remote control and notifications.

Relay Module: Acts as a switch, toggling the pump’s power supply on or off.

Sensors:

Water level sensors monitor tank/reservoir levels.

Flow sensors measure the pumped water’s flow rate.

Power Supply: Ensures stable operation—supporting the system even during power interruptions.

Applications

-

Irrigation Systems: Automates field watering based on soil moisture or preset schedules for agricultural use.

-

Water Supply Management: Manages pumps in municipal systems or residential tanks for consistent water delivery.

-

Industrial Processes: Controls fluid transfer in manufacturing and process environments to maintain efficient operations.

Benefits

-

Convenience: Remote access by SMS or app makes pump management effortless—ideal for use in remote or hard-to-reach locations.

-

Efficiency: Automated monitoring and control optimize pump operation, cutting energy consumption and conserving resources.

-

Reliability: Real-time alerts ensure fast fault detection and resolution, reducing downtime and preventing damage.